Key Insights

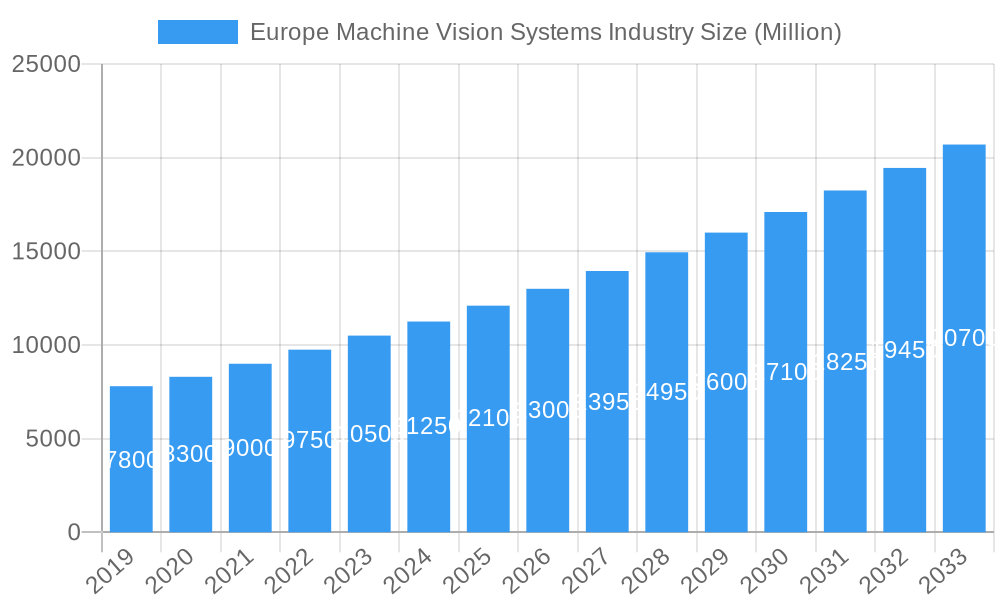

The European machine vision systems market is projected to reach $14.11 billion by 2025, driven by a robust Compound Annual Growth Rate (CAGR) of 7% through 2033. This expansion is fueled by escalating demand for automation and quality control across industries. Key growth drivers include the pursuit of enhanced manufacturing efficiency, stringent regulatory requirements for product quality in sectors like healthcare and pharmaceuticals, and the increasing adoption of Industry 4.0 principles. The automotive and electronics sectors are leading the integration of advanced machine vision for assembly, inspection, and defect detection. The burgeoning e-commerce landscape also propels adoption in logistics and retail for automated sorting, packaging, and inventory management. Innovations in AI and deep learning are further enhancing capabilities, enabling more sophisticated pattern recognition and data analysis, thereby expanding application scope.

Europe Machine Vision Systems Industry Market Size (In Billion)

The market segmentation is dynamic. While hardware components like vision systems, cameras, optics, illumination, and frame grabbers are foundational, software advancements increasingly define system intelligence and adaptability. The trend towards compact, powerful PC-based solutions and integrated smart cameras continues to grow, offering greater flexibility and cost-effectiveness. Geographically, Europe is a critical hub, with Germany, France, and the United Kingdom spearheading adoption due to strong industrial bases and early technological innovation. However, high initial investment costs for sophisticated systems and a potential shortage of skilled personnel may present challenges. Nevertheless, the overarching trend towards intelligent automation and data-driven decision-making is expected to overcome these hurdles, solidifying machine vision's indispensable role in European industries.

Europe Machine Vision Systems Industry Company Market Share

This report provides a comprehensive analysis of the Europe Machine Vision Systems Industry, examining current dynamics, future growth trajectories, and key market players. Leveraging extensive data and expert analysis, this study is essential for stakeholders seeking to understand the evolving landscape of vision technology, industrial automation, and AI in manufacturing. We provide granular insights into hardware components, software solutions, and diverse end-user industries, with precise market size figures in billion.

Europe Machine Vision Systems Industry Market Dynamics & Structure

The Europe Machine Vision Systems Industry is characterized by a dynamic interplay of innovation and adoption, driven by a strong emphasis on industrial automation and quality control. Market concentration is moderate, with key players like Keyence Corporation, Cognex Corporation, and Omron Corporation holding significant shares, yet a robust ecosystem of specialized providers fosters healthy competition. Technological innovation is a primary driver, with advancements in AI-powered inspection, 3D vision, and deep learning algorithms continuously pushing the boundaries of what machine vision can achieve. Omron's introduction of AI defect detection without learning samples in September 2020 exemplifies this trend. Regulatory frameworks, particularly concerning data privacy and industrial safety standards, are increasingly influencing system design and deployment. Competitive product substitutes exist, primarily in manual inspection and less sophisticated automation solutions, but the superior accuracy, speed, and consistency of machine vision systems create a strong value proposition. End-user demographics are shifting towards industries with high-volume production and stringent quality requirements, such as automotive, electronics and semiconductors, and food and beverage. Mergers and acquisitions (M&A) trends are visible as larger players consolidate their market positions and acquire innovative technologies. For instance, approximately 5-8 M&A deals are expected annually in the European market, focusing on niche technologies and regional expansion. Barriers to innovation include the high initial investment cost of advanced systems and the need for specialized expertise in implementation and maintenance.

Europe Machine Vision Systems Industry Growth Trends & Insights

The Europe Machine Vision Systems Industry is poised for robust expansion, fueled by an escalating demand for enhanced productivity, improved product quality, and reduced operational costs across various manufacturing sectors. The market size is projected to witness a Compound Annual Growth Rate (CAGR) of approximately 8.5% from the base year 2025 to 2033, reaching an estimated XXX Million units in value by the end of the forecast period. Historical data from 2019-2024 indicates a steady upward trajectory, with significant growth recorded in the post-pandemic recovery phase. Adoption rates of machine vision solutions are accelerating, driven by the increasing awareness of their benefits in automating complex inspection tasks, enabling predictive maintenance, and facilitating seamless integration with Industry 4.0 initiatives. Technological disruptions, such as the miniaturization of smart cameras, the development of more sophisticated imaging sensors, and the integration of edge computing capabilities, are further democratizing access to advanced vision technologies. Consumer behavior shifts, particularly in demanding higher quality and traceability in products, are indirectly influencing the adoption of machine vision for stringent quality control measures. The penetration of machine vision systems in the automotive industry for assembly verification and quality assurance is expected to exceed 70% by 2028. Similarly, the electronics and semiconductors segment is increasingly relying on high-precision vision systems for micro-component inspection and automated assembly, with market penetration estimated at 75% by 2029. The growing adoption of AI and machine learning algorithms within machine vision systems is a key growth accelerator, enabling systems to learn and adapt to new inspection challenges, thereby reducing the need for constant reprogramming and manual intervention. This trend is particularly evident in sectors like food and beverage for anomaly detection and in healthcare and pharmaceuticals for stringent quality control of medical devices and drug packaging. The logistic and retail sector is also witnessing increased adoption for automated sorting, inventory management, and package inspection, contributing significantly to the overall market growth.

Dominant Regions, Countries, or Segments in Europe Machine Vision Systems Industry

Within the Europe Machine Vision Systems Industry, the Hardware component segment, specifically Vision Systems and Cameras, stands out as the primary market driver, commanding an estimated 45% of the total market share in 2025. This dominance is further bolstered by the robust demand for Optics and Illumination Systems, which are integral to achieving high-quality imaging. Germany emerges as the leading country, accounting for approximately 30% of the European market share, owing to its strong automotive and electronics and semiconductors manufacturing base, both of which are heavy adopters of machine vision technologies. The country's commitment to Industry 4.0 principles and significant investment in automation infrastructure create a fertile ground for market growth.

Dominant Segments:

- Hardware (Vision Systems & Cameras): This segment's growth is fueled by the continuous innovation in sensor technology, offering higher resolution, faster frame rates, and enhanced sensitivity. The increasing complexity of manufacturing processes necessitates advanced vision hardware for precise quality control and automation. The estimated market size for vision systems and cameras in Europe is XXX Million units for 2025.

- End-User Industry - Automotive: The automotive sector's relentless pursuit of enhanced safety, quality, and manufacturing efficiency makes it a cornerstone of machine vision adoption. Applications range from robotic guidance and assembly verification to paint inspection and defect detection. The growth in electric vehicle production further amplifies the need for sophisticated vision systems in battery manufacturing and component assembly. The automotive segment is projected to contribute XXX Million units to the market in 2025.

- End-User Industry - Electronics and Semiconductors: The miniaturization of electronic components and the increasing complexity of semiconductor manufacturing demand ultra-high precision vision solutions. Machine vision is critical for wafer inspection, component placement, soldering inspection, and final product quality control. The segment's market size is estimated at XXX Million units in 2025.

Key Drivers for Dominance:

- Economic Policies: Government initiatives promoting advanced manufacturing, automation, and digitalization across Europe, particularly in Germany, France, and the UK, significantly boost machine vision adoption.

- Infrastructure Development: Investments in smart factories, advanced logistics networks, and Industry 4.0 initiatives create a supportive ecosystem for the deployment of machine vision systems.

- Technological Advancements: Continuous innovation in AI, deep learning, 3D vision, and sensor technology enables machine vision systems to tackle increasingly complex inspection and guidance tasks.

- Demand for Quality and Traceability: Stringent quality standards and the need for complete product traceability across industries like pharmaceuticals, food and beverage, and automotive are major growth catalysts.

The PC-based product segment also holds a significant market share, offering flexibility and computational power, though Smart Camera-based systems are gaining traction due to their ease of integration and compact design. The Healthcare and Pharmaceutical and Food and Beverage industries are also witnessing substantial growth, driven by regulatory requirements for sterile environments, precise packaging inspection, and food safety.

Europe Machine Vision Systems Industry Product Landscape

The Europe machine vision systems product landscape is characterized by rapid innovation and diversification, catering to a wide array of industrial needs. Key product innovations include high-resolution industrial cameras with enhanced sensitivity for low-light conditions, intelligent vision sensors capable of on-board processing, and advanced 3D vision systems for complex depth perception and volumetric measurements. Software solutions are increasingly focusing on user-friendly interfaces, AI-driven analytics for automated decision-making, and seamless integration with existing factory automation systems. Applications span from intricate defect detection in electronics and pharmaceuticals to robotic guidance in automotive assembly and quality control in food packaging. Performance metrics such as inspection speed, accuracy, and reliability continue to improve, enabling manufacturers to achieve higher throughput and lower error rates. Unique selling propositions often lie in specialized algorithms for defect classification, the ability to handle harsh industrial environments, and comprehensive data analytics capabilities for process optimization.

Key Drivers, Barriers & Challenges in Europe Machine Vision Systems Industry

Key Drivers:

- Industry 4.0 and Automation Push: The widespread adoption of smart manufacturing and automation technologies across Europe is a primary driver, necessitating advanced vision systems for quality control, inspection, and robotic guidance.

- Demand for Enhanced Quality and Traceability: Stricter regulatory requirements and consumer demand for high-quality, traceable products are compelling industries to invest in sophisticated machine vision solutions.

- Technological Advancements in AI and Deep Learning: The integration of AI and deep learning algorithms allows machine vision systems to perform complex tasks with greater accuracy and adaptability, driving innovation and adoption.

- Cost Reduction and Efficiency Gains: Machine vision systems contribute to significant operational cost savings by automating manual inspection, reducing waste, and improving production efficiency.

Barriers & Challenges:

- High Initial Investment Costs: The upfront expense of acquiring and implementing advanced machine vision systems can be a significant barrier for small and medium-sized enterprises (SMEs).

- Skilled Workforce Shortage: A lack of skilled personnel to install, configure, and maintain complex vision systems can hinder widespread adoption and effective utilization.

- Integration Complexity: Integrating new vision systems with legacy manufacturing equipment and IT infrastructure can be technically challenging and time-consuming.

- Data Security and Privacy Concerns: As vision systems collect and process sensitive production data, ensuring data security and compliance with privacy regulations (e.g., GDPR) is a growing concern. Supply chain disruptions and component shortages can also impact lead times and pricing, posing an ongoing challenge.

Emerging Opportunities in Europe Machine Vision Systems Industry

Emerging opportunities in the Europe Machine Vision Systems Industry lie in the untapped potential of niche applications and the evolution of existing ones. The increasing demand for sustainability and circular economy initiatives presents opportunities for vision systems in waste sorting, material identification, and product lifecycle management. The growth of the e-commerce sector is driving the need for automated warehousing, inventory management, and package inspection solutions. Furthermore, the expansion of cobots (collaborative robots) in manufacturing environments creates opportunities for vision-guided systems that can safely and efficiently work alongside human operators. The development of more accessible and user-friendly edge AI vision solutions is also opening up new markets for SMEs seeking to leverage automation.

Growth Accelerators in the Europe Machine Vision Systems Industry Industry

Several factors are acting as significant growth accelerators for the Europe Machine Vision Systems Industry. The relentless pace of technological breakthroughs, particularly in areas like neuromorphic computing for faster AI processing and hyperspectral imaging for advanced material analysis, will expand the capabilities and applications of machine vision. Strategic partnerships between machine vision providers, robotics companies, and software developers are fostering integrated solutions that address complex industrial challenges. For instance, collaborations on developing end-to-end automation platforms will streamline implementation and enhance value for end-users. Market expansion strategies, including penetration into emerging industrial sectors like renewable energy component manufacturing and advanced agricultural technology, will further fuel growth.

Key Players Shaping the Europe Machine Vision Systems Industry Market

- Keyence Corporation

- IDS Imaging Development Systems GmbH

- National Instruments Corporation

- Cognex Corporation

- Omron Corporation

- Uss Vision Inc

- Perceptron Inc

- Teledyne DALSA

- Datalogic SpA

- Basler AG

Notable Milestones in Europe Machine Vision Systems Industry Sector

- September 2020: Omron introduced a new FH Series Vision system, which includes the industry's first defect detection AI technology, which detects defects without learning samples. The artificial intelligence technology, which attempts to simulate sensibility and skilled inspector techniques, reliably detects previously complex defects, automating human vision-based visual inspection.

In-Depth Europe Machine Vision Systems Industry Market Outlook

The Europe Machine Vision Systems Industry is set for sustained and accelerated growth, driven by the ongoing digital transformation of manufacturing and logistics. Future market potential is significantly enhanced by the increasing integration of AI, enabling predictive maintenance, adaptive quality control, and intelligent automation. Strategic opportunities abound in catering to the evolving needs of sectors like electric vehicle production, personalized healthcare, and sustainable packaging. The continued advancements in sensor technology, computational power at the edge, and the development of industry-specific software solutions will unlock new applications and deepen market penetration across all end-user segments. Stakeholders who focus on offering integrated, intelligent, and scalable vision solutions are best positioned to capitalize on the robust growth trajectory of this dynamic industry.

Europe Machine Vision Systems Industry Segmentation

-

1. Component

-

1.1. Hardware

- 1.1.1. Vision Systems

- 1.1.2. Cameras

- 1.1.3. Optics and Illumination Systems

- 1.1.4. Frame Grabber

- 1.1.5. Other Types of Hardware

- 1.2. Software

-

1.1. Hardware

-

2. Product

- 2.1. PC-based

- 2.2. Smart Camera-based

-

3. End-User Industry

- 3.1. Food and Beverage

- 3.2. Healthcare and Pharmaceutical

- 3.3. Logistic and Retail

- 3.4. Automotive

- 3.5. Electronics and Semiconductors

- 3.6. Other End-user Industries

Europe Machine Vision Systems Industry Segmentation By Geography

-

1. Europe

- 1.1. United Kingdom

- 1.2. Germany

- 1.3. France

- 1.4. Italy

- 1.5. Spain

- 1.6. Netherlands

- 1.7. Belgium

- 1.8. Sweden

- 1.9. Norway

- 1.10. Poland

- 1.11. Denmark

Europe Machine Vision Systems Industry Regional Market Share

Geographic Coverage of Europe Machine Vision Systems Industry

Europe Machine Vision Systems Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 7% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasing Need for Quality Inspection and Automation; Rising Demand for Accurate Defect Detection

- 3.3. Market Restrains

- 3.3.1. Scarcity of Flexible Machine Vision Solutions

- 3.4. Market Trends

- 3.4.1. Automotive Industry to Witness Significant Growth

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Europe Machine Vision Systems Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Component

- 5.1.1. Hardware

- 5.1.1.1. Vision Systems

- 5.1.1.2. Cameras

- 5.1.1.3. Optics and Illumination Systems

- 5.1.1.4. Frame Grabber

- 5.1.1.5. Other Types of Hardware

- 5.1.2. Software

- 5.1.1. Hardware

- 5.2. Market Analysis, Insights and Forecast - by Product

- 5.2.1. PC-based

- 5.2.2. Smart Camera-based

- 5.3. Market Analysis, Insights and Forecast - by End-User Industry

- 5.3.1. Food and Beverage

- 5.3.2. Healthcare and Pharmaceutical

- 5.3.3. Logistic and Retail

- 5.3.4. Automotive

- 5.3.5. Electronics and Semiconductors

- 5.3.6. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Europe

- 5.1. Market Analysis, Insights and Forecast - by Component

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Keyence Corporation

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 IDS Imaging Development Systems GmbH

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 National Instruments Corporation

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Cognex Corporation

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Omron Corporation

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Uss Vision Inc

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Perceptron Inc

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Teledyne DALSA

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Datalogic SpA

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Basler AG

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 Keyence Corporation

List of Figures

- Figure 1: Europe Machine Vision Systems Industry Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Europe Machine Vision Systems Industry Share (%) by Company 2025

List of Tables

- Table 1: Europe Machine Vision Systems Industry Revenue billion Forecast, by Component 2020 & 2033

- Table 2: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Component 2020 & 2033

- Table 3: Europe Machine Vision Systems Industry Revenue billion Forecast, by Product 2020 & 2033

- Table 4: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Product 2020 & 2033

- Table 5: Europe Machine Vision Systems Industry Revenue billion Forecast, by End-User Industry 2020 & 2033

- Table 6: Europe Machine Vision Systems Industry Volume K Unit Forecast, by End-User Industry 2020 & 2033

- Table 7: Europe Machine Vision Systems Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 8: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Region 2020 & 2033

- Table 9: Europe Machine Vision Systems Industry Revenue billion Forecast, by Component 2020 & 2033

- Table 10: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Component 2020 & 2033

- Table 11: Europe Machine Vision Systems Industry Revenue billion Forecast, by Product 2020 & 2033

- Table 12: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Product 2020 & 2033

- Table 13: Europe Machine Vision Systems Industry Revenue billion Forecast, by End-User Industry 2020 & 2033

- Table 14: Europe Machine Vision Systems Industry Volume K Unit Forecast, by End-User Industry 2020 & 2033

- Table 15: Europe Machine Vision Systems Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 16: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Country 2020 & 2033

- Table 17: United Kingdom Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 18: United Kingdom Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 19: Germany Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 20: Germany Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 21: France Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 22: France Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 23: Italy Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 24: Italy Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 25: Spain Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 26: Spain Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 27: Netherlands Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 28: Netherlands Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 29: Belgium Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 30: Belgium Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 31: Sweden Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 32: Sweden Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 33: Norway Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 34: Norway Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 35: Poland Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 36: Poland Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 37: Denmark Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 38: Denmark Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Europe Machine Vision Systems Industry?

The projected CAGR is approximately 7%.

2. Which companies are prominent players in the Europe Machine Vision Systems Industry?

Key companies in the market include Keyence Corporation, IDS Imaging Development Systems GmbH, National Instruments Corporation, Cognex Corporation, Omron Corporation, Uss Vision Inc, Perceptron Inc, Teledyne DALSA, Datalogic SpA, Basler AG.

3. What are the main segments of the Europe Machine Vision Systems Industry?

The market segments include Component, Product, End-User Industry.

4. Can you provide details about the market size?

The market size is estimated to be USD 14.11 billion as of 2022.

5. What are some drivers contributing to market growth?

Increasing Need for Quality Inspection and Automation; Rising Demand for Accurate Defect Detection.

6. What are the notable trends driving market growth?

Automotive Industry to Witness Significant Growth.

7. Are there any restraints impacting market growth?

Scarcity of Flexible Machine Vision Solutions.

8. Can you provide examples of recent developments in the market?

September 2020 - Omron introduced a new FH Series Vision system, which includes the industry's first defect detection AI technology, which detects defects without learning samples. The artificial intelligence technology, which attempts to simulate sensibility and skilled inspector techniques, reliably detects previously complex defects, automating human vision-based visual inspection.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 4950, and USD 6800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion and volume, measured in K Unit.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Europe Machine Vision Systems Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Europe Machine Vision Systems Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Europe Machine Vision Systems Industry?

To stay informed about further developments, trends, and reports in the Europe Machine Vision Systems Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence