Key Insights

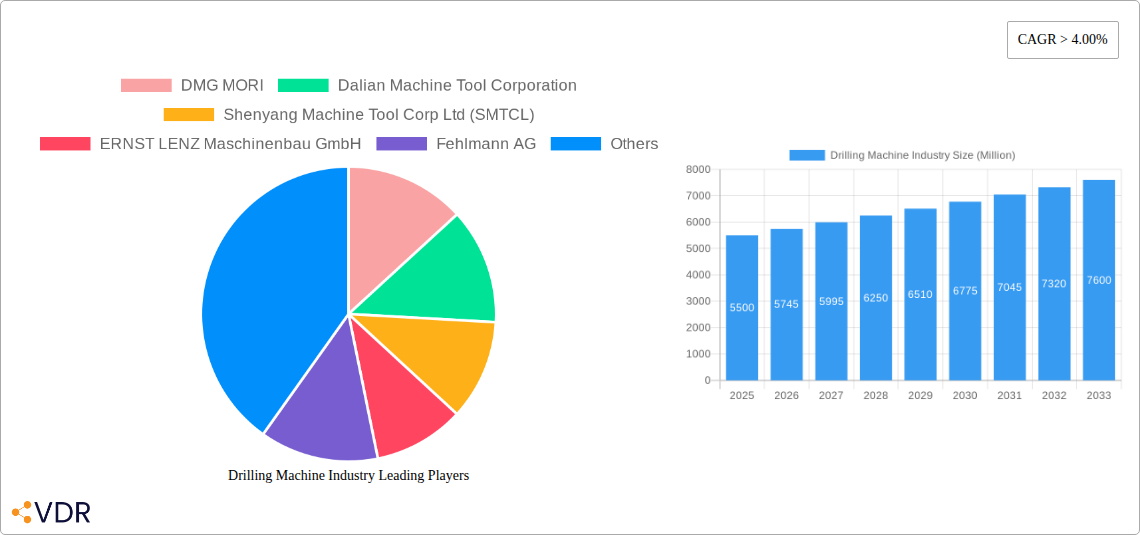

The global drilling machine market is projected for significant expansion, estimated at USD 26.56 billion in 2025, with a projected CAGR of 6%. This growth is propelled by industrial automation, advanced manufacturing technologies, and demand from aerospace, automotive, and energy sectors. The market is anticipated to reach over USD 7.8 billion by 2033. Key drivers include the need for precision drilling in complex manufacturing and the adoption of advanced machines like multi-spindle and deep hole drills. Fabrication, industrial machinery, and automotive industries, supported by global manufacturing output and infrastructure development, will be major contributors.

Drilling Machine Industry Market Size (In Billion)

The integration of Industry 4.0, including IoT and AI, for enhanced drilling machine efficiency and predictive maintenance is a key trend. Growing demand for specialized drilling in aerospace and oil & gas sectors presents new opportunities. Restraints include high initial investment and fluctuating raw material prices. Asia Pacific is expected to lead the market due to its robust manufacturing base and industrial modernization efforts.

Drilling Machine Industry Company Market Share

Gain comprehensive insights into the global drilling machine market (2019-2033, base year 2025). This report analyzes market dynamics, growth trends, regional leadership, product innovations, and key players in drilling technology. An essential resource for professionals, investors, and strategists navigating the evolving drilling machinery landscape, from sensitive and upright to deep hole and multi-spindle machines.

Drilling Machine Industry Market Dynamics & Structure

The global drilling machine industry exhibits a moderately concentrated market structure, with a few dominant players alongside a robust network of specialized manufacturers. Technological innovation is a key driver, fueled by advancements in automation, precision engineering, and the integration of Industry 4.0 principles, leading to the development of more efficient and versatile drilling solutions. Regulatory frameworks, primarily focused on safety standards and environmental compliance, influence product development and manufacturing processes. Competitive product substitutes, such as advanced machining centers offering multi-functional capabilities, pose a constant challenge, necessitating continuous innovation from drilling machine manufacturers. End-user demographics are increasingly diverse, with significant demand stemming from fabrication and industrial machinery manufacturing, automotive, aerospace, and the burgeoning energy sector, including oil & gas. Mergers and acquisitions (M&A) are an integral part of the market's evolution, with strategic consolidations aimed at expanding product portfolios, gaining market access, and leveraging technological synergies. For instance, the acquisition of PAMA by Nidec Corporation in November 2022 signals a trend of consolidation within the machine tool sector.

- Market Concentration: Moderately concentrated with key global players and numerous niche manufacturers.

- Technological Innovation: Driven by automation, Industry 4.0, precision control, and advanced materials.

- Regulatory Influence: Safety standards (e.g., CE marking) and environmental regulations shape product design.

- Competitive Landscape: Competition from multi-functional machining centers requires specialized value propositions.

- End-User Diversification: Strong demand from manufacturing, automotive, aerospace, and energy sectors.

- M&A Activity: Strategic acquisitions to enhance market position and technological capabilities.

Drilling Machine Industry Growth Trends & Insights

The global drilling machine industry is poised for significant growth over the forecast period, driven by a confluence of industrial expansion, technological advancements, and evolving end-user demands. The market size is projected to experience a healthy CAGR, with an estimated market value of over $25,000 Million units in 2025. This growth is propelled by increased adoption of advanced drilling technologies, including CNC-controlled drilling machines, automated drilling systems, and specialized deep hole drilling solutions, which offer enhanced precision, speed, and efficiency across various applications. Technological disruptions, such as the integration of AI and machine learning for predictive maintenance and process optimization, are further enhancing the value proposition of modern drilling equipment. Consumer behavior shifts are characterized by a growing preference for customized solutions, energy-efficient machinery, and integrated manufacturing systems. The sustained demand from key sectors like automotive for lightweight component manufacturing, aerospace for precision drilling in complex structures, and the energy industry for exploration and infrastructure development, will act as strong growth catalysts. The increasing adoption of smart manufacturing principles and the overall trend towards industrial automation are also playing a pivotal role in shaping the market's upward trajectory.

- Market Size Evolution: Projected to grow substantially, reaching over $35,000 Million units by 2033.

- Adoption Rates: Increasing adoption of CNC, automation, and specialized drilling technologies.

- Technological Disruptions: AI integration, IoT connectivity, and advanced metrology are transforming drilling capabilities.

- Consumer Behavior Shifts: Demand for customization, energy efficiency, and integrated solutions.

- Key Growth Drivers: Industrial automation, infrastructure development, and demand for precision manufacturing.

Dominant Regions, Countries, or Segments in Drilling Machine Industry

The Fabrication and Industrial Machinery Manufacturing segment stands out as the dominant force driving market growth within the global drilling machine industry. This segment encompasses a vast array of applications, from small-scale workshops to large-scale manufacturing plants, all of which rely on drilling machines for fundamental production processes. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, emerges as the leading geographical area, owing to its robust manufacturing base, significant industrial output, and continuous investment in technological upgrades. The presence of major industrial machinery manufacturers and a strong demand for precision components across various sectors, including automotive and electronics, further solidifies Asia-Pacific's dominance.

Within the Type segment, Upright Drilling Machines and Sensitive Drilling Machines continue to hold significant market share due to their versatility and widespread use in general fabrication and small to medium-sized operations. However, Deep Hole Drilling Machines are witnessing substantial growth, driven by specialized applications in the oil & gas, defense, and aerospace industries where precision and depth are critical. The End-user segment of Automotive is a key growth driver, fueled by the increasing complexity of vehicle components, the demand for lightweight materials requiring precise drilling, and the overall expansion of automotive production globally. The Energy Industry, encompassing oil & gas and renewable energy infrastructure, also represents a critical and growing end-user market, necessitating robust drilling solutions for exploration, extraction, and construction.

- Dominant Segment (End-user): Fabrication and Industrial Machinery Manufacturing, accounting for over 30% of the market share.

- Dominant Region: Asia-Pacific, driven by China's manufacturing prowess and technological advancements.

- Key Country (within Asia-Pacific): China, with its extensive industrial base and demand for diverse drilling solutions.

- Growing Segment (Type): Deep Hole Drilling Machines, propelled by demand in specialized industries.

- Key End-User Growth Drivers: Automotive sector's expansion and the energy industry's infrastructure development.

- Market Penetration: High penetration in general manufacturing, with increasing adoption in high-precision sectors.

Drilling Machine Industry Product Landscape

The drilling machine industry is characterized by a diverse product landscape, ranging from highly specialized Deep Hole Drilling Machines designed for exceptionally precise and deep bore operations, to versatile Upright Drilling Machines and Sensitive Drilling Machines suitable for a wide array of general-purpose fabrication tasks. Innovations are focused on enhancing speed, accuracy, and automation. Manufacturers are increasingly integrating advanced CNC control systems, enabling complex drilling patterns and tight tolerances. The development of multi-spindle drilling machines caters to high-volume production needs, significantly reducing cycle times. Performance metrics are being redefined by improvements in spindle speed, feed rates, power efficiency, and tool life. Unique selling propositions often lie in the machine's ability to handle specific materials, its energy consumption, or its integration capabilities within smart factory ecosystems.

Key Drivers, Barriers & Challenges in Drilling Machine Industry

Key Drivers:

- Industrial Automation & Industry 4.0: The widespread adoption of automated manufacturing processes and smart factory initiatives is a primary growth accelerator.

- Infrastructure Development: Global investments in infrastructure projects, including energy, transportation, and construction, significantly boost demand for drilling machinery.

- Technological Advancements: Continuous innovation in precision engineering, CNC technology, and materials science leads to the development of more efficient and capable drilling machines.

- Automotive & Aerospace Sector Growth: The expanding production of vehicles and aircraft, with their complex component requirements, drives demand for specialized drilling solutions.

Barriers & Challenges:

- Supply Chain Disruptions: Global supply chain volatility and raw material price fluctuations can impact production costs and lead times.

- High Initial Investment Cost: The upfront cost of advanced drilling machines can be a barrier for small and medium-sized enterprises (SMEs).

- Skilled Labor Shortage: A lack of trained operators and maintenance personnel for sophisticated drilling equipment can hinder adoption.

- Intense Competition: The market faces strong competition from both established players and emerging manufacturers, putting pressure on pricing and profit margins.

- Economic Slowdowns: Global economic downturns can lead to reduced capital expenditure by end-users, impacting demand for machinery.

Emerging Opportunities in Drilling Machine Industry

Emerging opportunities in the drilling machine industry are primarily centered around smart manufacturing integration and niche applications. The increasing demand for customized and adaptable drilling solutions for specialized industries like medical device manufacturing and advanced composites presents a significant growth avenue. Furthermore, the development of energy-efficient drilling machines powered by sustainable technologies aligns with global environmental initiatives and offers a competitive advantage. The integration of AI-powered diagnostics and predictive maintenance into drilling machines creates opportunities for service-based revenue streams and enhanced customer value. The growing adoption of additive manufacturing (3D printing) is also creating new demands for post-processing and precision drilling on 3D-printed parts.

Growth Accelerators in the Drilling Machine Industry Industry

The drilling machine industry's long-term growth will be significantly accelerated by continued technological breakthroughs in areas such as advanced materials processing, robotics, and intelligent control systems. Strategic partnerships and collaborations between machine tool manufacturers, software providers, and end-users will foster innovation and unlock new application potentials. The expansion into emerging markets with burgeoning industrial sectors and the increasing focus on high-precision drilling for advanced manufacturing sectors like aerospace and medical devices will further propel sustained growth. The development of modular and reconfigurable drilling systems that can adapt to evolving production needs will also be a key growth catalyst.

Key Players Shaping the Drilling Machine Industry Market

- DMG MORI

- Dalian Machine Tool Corporation

- Shenyang Machine Tool Corp Ltd (SMTCL)

- ERNST LENZ Maschinenbau GmbH

- Fehlmann AG

- Gate Machinery International Limited

- Hsin Geeli Hardware Enterprise

- Kaufman Mfg Co

- LTF SpA

- Minitool Inc

- Roku-Roku Co Ltd

- Scantool Group

- Taiwan Winnerstech Machinery Co Ltd

- Tongtai Machine & Tool Co Ltd

Notable Milestones in Drilling Machine Industry Sector

- December 2022: Komatsu Limited (a Japanese manufacturing company) announced its agreement to acquire GHH Group GmbH (GHH), a manufacturer of underground mining, tunneling, and special civil engineering equipment headquartered in Gelsenkirchen, Germany. This acquisition significantly strengthens Komatsu's position in the underground mining equipment sector and is expected to accelerate new product development.

- November 2022: Nidec Corporation (a Japanese manufacturer and distributor) acquired PAMA (an Italian producer of machine tools) and its nine affiliate companies. The deal, estimated at 15 billion yen (USD 108 million), brought in over USD 124 million in sales in 2021 and expanded Nidec's machine tool capabilities with PAMA's production bases in Italy and China.

In-Depth Drilling Machine Industry Market Outlook

The drilling machine industry is set for a robust future, driven by continuous technological innovation and expanding applications. The increasing demand for precision and automation across key sectors like automotive, aerospace, and energy will continue to be a primary growth engine. Opportunities lie in the development of intelligent, connected drilling machines that offer enhanced data analytics and predictive capabilities, as well as solutions tailored for emerging industries and sustainable manufacturing practices. Strategic collaborations and a focus on delivering value-added services will be crucial for market leaders to capitalize on the dynamic growth potential. The industry is well-positioned to benefit from the global drive towards advanced manufacturing and efficient industrial processes.

Drilling Machine Industry Segmentation

-

1. Type

- 1.1. Sensitive Drilling Machine

- 1.2. Upright Drilling Machine

- 1.3. Radial Drilling Machine

- 1.4. Gang Drilling Machine

- 1.5. Multiple Spindle Drilling Machine

- 1.6. Deep Hole Drilling Machine

- 1.7. Other Types

-

2. End-user

- 2.1. Fabrication and Industrial Machinery Manufacturing

- 2.2. Aerospace

- 2.3. Heavy Equipment

- 2.4. Automotive

- 2.5. Energy Industry

- 2.6. Military & Defense

- 2.7. Oil & Gas

- 2.8. Other End-Users

Drilling Machine Industry Segmentation By Geography

- 1. North America

- 2. Europe

- 3. Asia Pacific

- 4. Middle East and Africa

- 5. Latin America

Drilling Machine Industry Regional Market Share

Geographic Coverage of Drilling Machine Industry

Drilling Machine Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Rise in Demand for Drilling Machines in the Automotive Industry

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Drilling Machine Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Sensitive Drilling Machine

- 5.1.2. Upright Drilling Machine

- 5.1.3. Radial Drilling Machine

- 5.1.4. Gang Drilling Machine

- 5.1.5. Multiple Spindle Drilling Machine

- 5.1.6. Deep Hole Drilling Machine

- 5.1.7. Other Types

- 5.2. Market Analysis, Insights and Forecast - by End-user

- 5.2.1. Fabrication and Industrial Machinery Manufacturing

- 5.2.2. Aerospace

- 5.2.3. Heavy Equipment

- 5.2.4. Automotive

- 5.2.5. Energy Industry

- 5.2.6. Military & Defense

- 5.2.7. Oil & Gas

- 5.2.8. Other End-Users

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. Europe

- 5.3.3. Asia Pacific

- 5.3.4. Middle East and Africa

- 5.3.5. Latin America

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America Drilling Machine Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Sensitive Drilling Machine

- 6.1.2. Upright Drilling Machine

- 6.1.3. Radial Drilling Machine

- 6.1.4. Gang Drilling Machine

- 6.1.5. Multiple Spindle Drilling Machine

- 6.1.6. Deep Hole Drilling Machine

- 6.1.7. Other Types

- 6.2. Market Analysis, Insights and Forecast - by End-user

- 6.2.1. Fabrication and Industrial Machinery Manufacturing

- 6.2.2. Aerospace

- 6.2.3. Heavy Equipment

- 6.2.4. Automotive

- 6.2.5. Energy Industry

- 6.2.6. Military & Defense

- 6.2.7. Oil & Gas

- 6.2.8. Other End-Users

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. Europe Drilling Machine Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Sensitive Drilling Machine

- 7.1.2. Upright Drilling Machine

- 7.1.3. Radial Drilling Machine

- 7.1.4. Gang Drilling Machine

- 7.1.5. Multiple Spindle Drilling Machine

- 7.1.6. Deep Hole Drilling Machine

- 7.1.7. Other Types

- 7.2. Market Analysis, Insights and Forecast - by End-user

- 7.2.1. Fabrication and Industrial Machinery Manufacturing

- 7.2.2. Aerospace

- 7.2.3. Heavy Equipment

- 7.2.4. Automotive

- 7.2.5. Energy Industry

- 7.2.6. Military & Defense

- 7.2.7. Oil & Gas

- 7.2.8. Other End-Users

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Asia Pacific Drilling Machine Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Sensitive Drilling Machine

- 8.1.2. Upright Drilling Machine

- 8.1.3. Radial Drilling Machine

- 8.1.4. Gang Drilling Machine

- 8.1.5. Multiple Spindle Drilling Machine

- 8.1.6. Deep Hole Drilling Machine

- 8.1.7. Other Types

- 8.2. Market Analysis, Insights and Forecast - by End-user

- 8.2.1. Fabrication and Industrial Machinery Manufacturing

- 8.2.2. Aerospace

- 8.2.3. Heavy Equipment

- 8.2.4. Automotive

- 8.2.5. Energy Industry

- 8.2.6. Military & Defense

- 8.2.7. Oil & Gas

- 8.2.8. Other End-Users

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Middle East and Africa Drilling Machine Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Sensitive Drilling Machine

- 9.1.2. Upright Drilling Machine

- 9.1.3. Radial Drilling Machine

- 9.1.4. Gang Drilling Machine

- 9.1.5. Multiple Spindle Drilling Machine

- 9.1.6. Deep Hole Drilling Machine

- 9.1.7. Other Types

- 9.2. Market Analysis, Insights and Forecast - by End-user

- 9.2.1. Fabrication and Industrial Machinery Manufacturing

- 9.2.2. Aerospace

- 9.2.3. Heavy Equipment

- 9.2.4. Automotive

- 9.2.5. Energy Industry

- 9.2.6. Military & Defense

- 9.2.7. Oil & Gas

- 9.2.8. Other End-Users

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Latin America Drilling Machine Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Sensitive Drilling Machine

- 10.1.2. Upright Drilling Machine

- 10.1.3. Radial Drilling Machine

- 10.1.4. Gang Drilling Machine

- 10.1.5. Multiple Spindle Drilling Machine

- 10.1.6. Deep Hole Drilling Machine

- 10.1.7. Other Types

- 10.2. Market Analysis, Insights and Forecast - by End-user

- 10.2.1. Fabrication and Industrial Machinery Manufacturing

- 10.2.2. Aerospace

- 10.2.3. Heavy Equipment

- 10.2.4. Automotive

- 10.2.5. Energy Industry

- 10.2.6. Military & Defense

- 10.2.7. Oil & Gas

- 10.2.8. Other End-Users

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 DMG MORI

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Dalian Machine Tool Corporation

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Shenyang Machine Tool Corp Ltd (SMTCL)

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 ERNST LENZ Maschinenbau GmbH

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Fehlmann AG

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Gate Machinery International Limited

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Hsin Geeli Hardware Enterprise

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Kaufman Mfg Co

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 LTF SpA

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Minitool Inc

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Roku-Roku Co Ltd

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Scantool Group

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 Taiwan Winnerstech Machinery Co Ltd

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Tongtai Machine & Tool Co Ltd**List Not Exhaustive

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.1 DMG MORI

List of Figures

- Figure 1: Global Drilling Machine Industry Revenue Breakdown (billion, %) by Region 2025 & 2033

- Figure 2: North America Drilling Machine Industry Revenue (billion), by Type 2025 & 2033

- Figure 3: North America Drilling Machine Industry Revenue Share (%), by Type 2025 & 2033

- Figure 4: North America Drilling Machine Industry Revenue (billion), by End-user 2025 & 2033

- Figure 5: North America Drilling Machine Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 6: North America Drilling Machine Industry Revenue (billion), by Country 2025 & 2033

- Figure 7: North America Drilling Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 8: Europe Drilling Machine Industry Revenue (billion), by Type 2025 & 2033

- Figure 9: Europe Drilling Machine Industry Revenue Share (%), by Type 2025 & 2033

- Figure 10: Europe Drilling Machine Industry Revenue (billion), by End-user 2025 & 2033

- Figure 11: Europe Drilling Machine Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 12: Europe Drilling Machine Industry Revenue (billion), by Country 2025 & 2033

- Figure 13: Europe Drilling Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 14: Asia Pacific Drilling Machine Industry Revenue (billion), by Type 2025 & 2033

- Figure 15: Asia Pacific Drilling Machine Industry Revenue Share (%), by Type 2025 & 2033

- Figure 16: Asia Pacific Drilling Machine Industry Revenue (billion), by End-user 2025 & 2033

- Figure 17: Asia Pacific Drilling Machine Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 18: Asia Pacific Drilling Machine Industry Revenue (billion), by Country 2025 & 2033

- Figure 19: Asia Pacific Drilling Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 20: Middle East and Africa Drilling Machine Industry Revenue (billion), by Type 2025 & 2033

- Figure 21: Middle East and Africa Drilling Machine Industry Revenue Share (%), by Type 2025 & 2033

- Figure 22: Middle East and Africa Drilling Machine Industry Revenue (billion), by End-user 2025 & 2033

- Figure 23: Middle East and Africa Drilling Machine Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 24: Middle East and Africa Drilling Machine Industry Revenue (billion), by Country 2025 & 2033

- Figure 25: Middle East and Africa Drilling Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Latin America Drilling Machine Industry Revenue (billion), by Type 2025 & 2033

- Figure 27: Latin America Drilling Machine Industry Revenue Share (%), by Type 2025 & 2033

- Figure 28: Latin America Drilling Machine Industry Revenue (billion), by End-user 2025 & 2033

- Figure 29: Latin America Drilling Machine Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 30: Latin America Drilling Machine Industry Revenue (billion), by Country 2025 & 2033

- Figure 31: Latin America Drilling Machine Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Drilling Machine Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 2: Global Drilling Machine Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 3: Global Drilling Machine Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 4: Global Drilling Machine Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 5: Global Drilling Machine Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 6: Global Drilling Machine Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 7: Global Drilling Machine Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 8: Global Drilling Machine Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 9: Global Drilling Machine Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 10: Global Drilling Machine Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 11: Global Drilling Machine Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 12: Global Drilling Machine Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 13: Global Drilling Machine Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 14: Global Drilling Machine Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 15: Global Drilling Machine Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 16: Global Drilling Machine Industry Revenue billion Forecast, by Type 2020 & 2033

- Table 17: Global Drilling Machine Industry Revenue billion Forecast, by End-user 2020 & 2033

- Table 18: Global Drilling Machine Industry Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Drilling Machine Industry?

The projected CAGR is approximately 6%.

2. Which companies are prominent players in the Drilling Machine Industry?

Key companies in the market include DMG MORI, Dalian Machine Tool Corporation, Shenyang Machine Tool Corp Ltd (SMTCL), ERNST LENZ Maschinenbau GmbH, Fehlmann AG, Gate Machinery International Limited, Hsin Geeli Hardware Enterprise, Kaufman Mfg Co, LTF SpA, Minitool Inc, Roku-Roku Co Ltd, Scantool Group, Taiwan Winnerstech Machinery Co Ltd, Tongtai Machine & Tool Co Ltd**List Not Exhaustive.

3. What are the main segments of the Drilling Machine Industry?

The market segments include Type, End-user.

4. Can you provide details about the market size?

The market size is estimated to be USD 26.56 billion as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Rise in Demand for Drilling Machines in the Automotive Industry.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

December 2022: Komatsu Limited (a Japanese manufacturing company) announced that it has agreed to acquire GHH Group GmbH (GHH), a manufacturer of underground mining, tunneling, and special civil engineering equipment headquartered in Gelsenkirchen, Germany. This acquisition represents a great opportunity for Komatsu to expand its offerings for underground mining equipment and accelerate new product development through synergies with Komatsu's existing team and product offerings.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Drilling Machine Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Drilling Machine Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Drilling Machine Industry?

To stay informed about further developments, trends, and reports in the Drilling Machine Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence