Key Insights

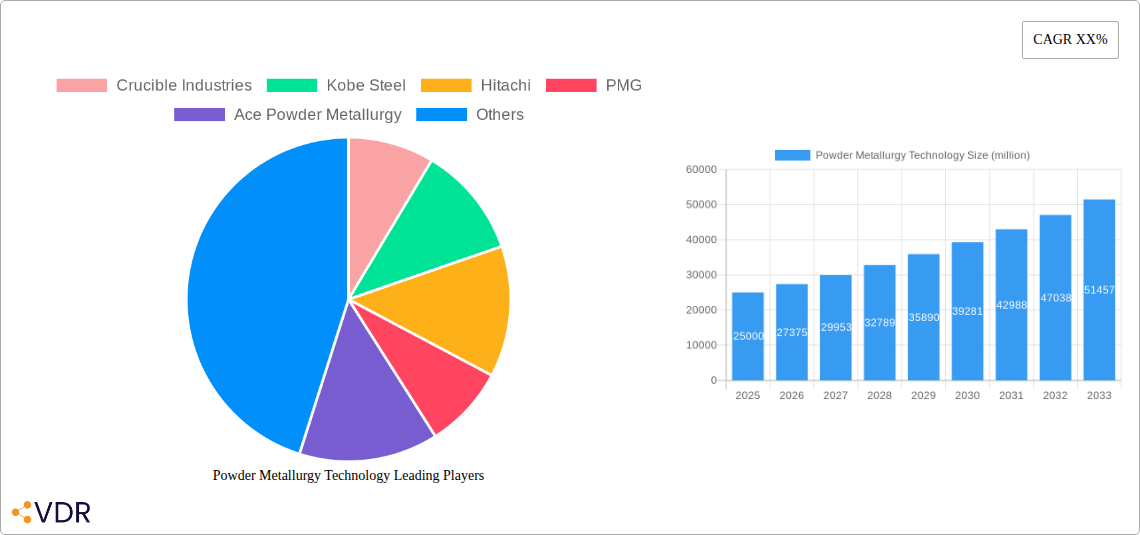

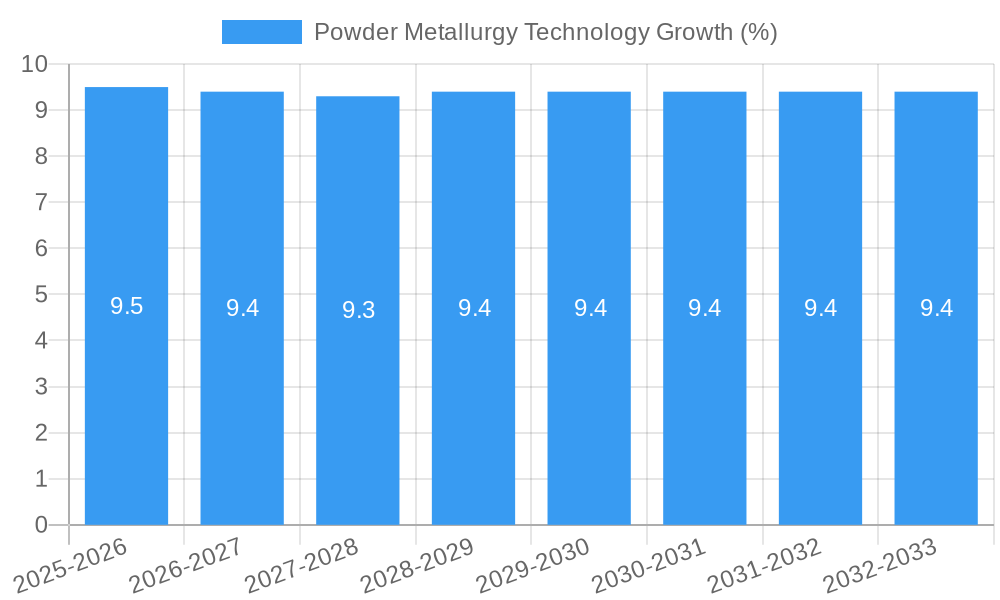

The global Powder Metallurgy Technology market is projected to reach a substantial valuation, estimated at approximately USD 25,000 million by 2025, and is expected to exhibit robust growth at a Compound Annual Growth Rate (CAGR) of around 9.5% through 2033. This significant expansion is fueled by the inherent advantages of powder metallurgy, including its ability to create complex parts with high precision, excellent material utilization, and cost-effectiveness, particularly for mass production. Key drivers include the burgeoning demand from the automotive sector, where lightweight and durable components are paramount for fuel efficiency and performance enhancement, and the rapidly evolving electrical and electronics industry, which relies on intricate, high-performance parts. The industrial sector also represents a considerable growth area, with powder metallurgy finding applications in heavy machinery, power tools, and manufacturing equipment due to its superior mechanical properties and wear resistance.

Further underpinning this market's ascent are technological advancements in powder production and sintering processes, enabling the creation of novel alloys and materials with tailored properties. Emerging trends such as the increasing adoption of additive manufacturing (3D printing) using metal powders, the development of advanced ceramic and composite powders, and the growing focus on sustainable manufacturing practices—where powder metallurgy offers significant material savings—are poised to accelerate market penetration. However, the market faces certain restraints, including the initial capital investment required for sophisticated powder metallurgy equipment and the relatively specialized nature of the technology, which can limit its widespread adoption in certain niche applications or by smaller manufacturers. Despite these challenges, the intrinsic benefits and continuous innovation within powder metallurgy technologies ensure a dynamic and expanding market landscape.

This comprehensive report offers an in-depth analysis of the global Powder Metallurgy Technology market, exploring its current state, growth trajectory, and future potential. With a focus on key applications, material types, and emerging industry trends, this report is an indispensable resource for stakeholders seeking to navigate and capitalize on this dynamic sector. Leveraging high-traffic keywords and a structured format, this report maximizes SEO visibility and delivers actionable insights for industry professionals.

Powder Metallurgy Technology Market Dynamics & Structure

The global Powder Metallurgy Technology market is characterized by a moderate level of concentration, with key players like Hoganas AB, GKN, and Sumitomo Electric Industries holding significant market shares. Technological innovation remains a primary driver, fueled by advancements in powder production, pressing techniques, and sintering processes that enable the creation of complex geometries and enhanced material properties. Regulatory frameworks, particularly those related to environmental standards and material safety, are increasingly influencing market dynamics. Competitive product substitutes, such as traditional machining and casting, are being challenged by the superior performance and cost-effectiveness offered by powder metallurgy for specific applications. End-user demographics are shifting towards industries demanding lightweight, high-strength, and precisely engineered components. Merger and acquisition (M&A) trends indicate a strategic consolidation among leading firms to expand technological capabilities and market reach.

- Market Concentration: Moderate, with a few dominant global players.

- Technological Innovation: Driven by advanced powder production, pressing, and sintering.

- Regulatory Influence: Growing importance of environmental and safety standards.

- Competitive Landscape: Challenging traditional manufacturing methods like machining and casting.

- End-User Evolution: Increasing demand from automotive, aerospace, and medical sectors.

- M&A Activity: Strategic consolidations for enhanced capabilities and market access.

Powder Metallurgy Technology Growth Trends & Insights

The global Powder Metallurgy Technology market is poised for robust growth, driven by its ability to produce complex, high-performance components with reduced material waste and improved efficiency. The market size is projected to experience a significant expansion from an estimated $23,500 million in 2025 to an anticipated $35,800 million by 2033, exhibiting a Compound Annual Growth Rate (CAGR) of approximately 5.3% during the forecast period. Adoption rates are accelerating across various industries, notably the automotive sector, where lightweighting initiatives and the demand for more sophisticated engine and transmission parts are significant drivers. Technological disruptions, including advancements in additive manufacturing (3D printing) using metal powders and the development of novel alloy powders with superior properties, are further reshaping the market. Consumer behavior shifts are favoring products that offer enhanced durability, reduced energy consumption, and greater customization, all of which can be achieved through powder metallurgy.

- Market Size Evolution: Expected to grow from $23,500 million in 2025 to $35,800 million by 2033.

- CAGR: Approximately 5.3% during the forecast period (2025–2033).

- Adoption Rates: Accelerating across key industries, especially automotive.

- Technological Disruptions: Additive manufacturing and novel alloy powder development.

- Consumer Behavior: Driving demand for durable, energy-efficient, and customizable products.

- Market Penetration: Increasing in emerging economies and advanced manufacturing segments.

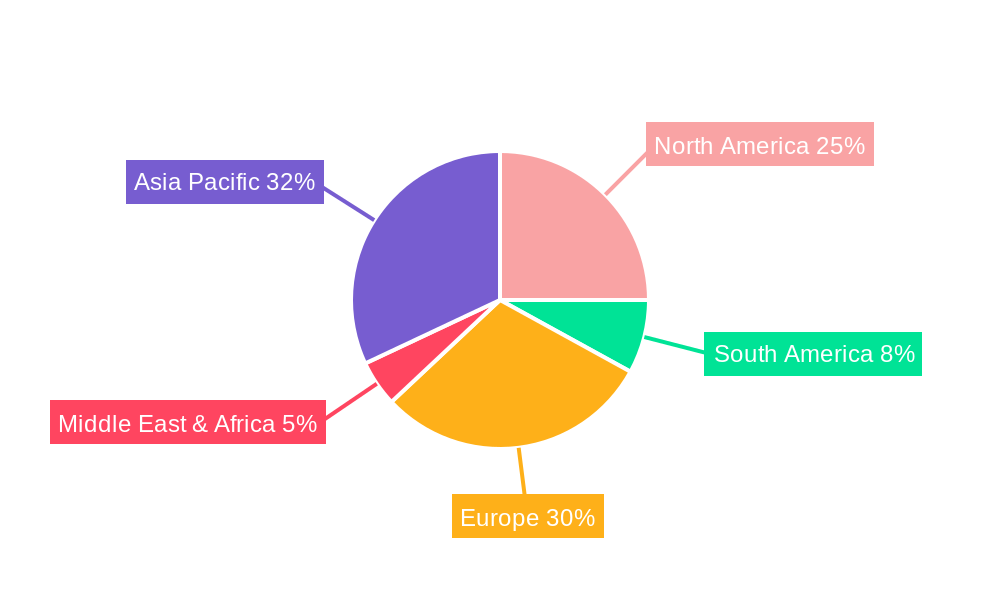

Dominant Regions, Countries, or Segments in Powder Metallurgy Technology

The Automotive application segment is the undisputed leader in the global Powder Metallurgy Technology market, driven by the relentless pursuit of fuel efficiency, reduced emissions, and enhanced performance. This segment is projected to contribute significantly to the overall market valuation, with an estimated market share of over 40% in 2025. The demand for lightweight and structurally sound components, such as gears, bearings, connecting rods, and structural parts, in internal combustion engines, electric vehicles, and transmissions, makes powder metallurgy an ideal manufacturing solution. Countries like Germany, Japan, and the United States, with their strong automotive manufacturing bases and advanced technological adoption, are leading the regional demand within this segment. Furthermore, the increasing complexity of automotive designs and the need for cost-effective mass production solutions solidify the automotive sector's dominance.

- Dominant Segment: Automotive Application.

- Key Drivers in Automotive: Lightweighting initiatives, fuel efficiency mandates, electric vehicle component demand.

- Leading Component Types: Gears, bearings, connecting rods, structural parts.

- Dominant Regions for Automotive PM: Germany, Japan, United States.

- Growth Potential: Continued innovation in EV powertrains and autonomous driving components.

The Metallic Material (Powder Metallurgy Steel) type segment is also a cornerstone of the Powder Metallurgy Technology market, representing a substantial portion of the market's revenue. In 2025, this segment is estimated to hold a market share of approximately 55% of the total material types. The versatility, cost-effectiveness, and tunable properties of powder metallurgy steel make it indispensable for a wide array of applications. Its ability to achieve high strength-to-weight ratios and complex shapes without extensive post-processing is a key advantage. The ongoing development of advanced steel powders with enhanced corrosion resistance, wear resistance, and high-temperature performance further fuels its dominance.

- Dominant Type: Metallic Material (Powder Metallurgy Steel).

- Market Share (Material Type): Estimated at 55% in 2025.

- Key Advantages: Versatility, cost-effectiveness, tunable properties, high strength-to-weight ratio.

- Advancements: Improved corrosion, wear, and high-temperature resistance.

- Growth Drivers: Expanding applications in industrial machinery and consumer goods.

Powder Metallurgy Technology Product Landscape

The Powder Metallurgy Technology product landscape is defined by its continuous evolution, yielding components with unparalleled precision and performance. Innovations are concentrated on developing novel alloy powders, such as high-entropy alloys and advanced stainless steels, which offer superior mechanical properties, corrosion resistance, and thermal stability. Applications are rapidly expanding beyond traditional automotive and industrial uses into aerospace, medical implants, and additive manufacturing. Performance metrics like tensile strength, fatigue life, and density are being pushed to new limits through optimized powder compositions and advanced sintering techniques. Unique selling propositions include the ability to create net-shape or near-net-shape parts, thereby minimizing material waste and machining costs, and the capability to produce intricate designs that are unachievable with conventional manufacturing methods.

Key Drivers, Barriers & Challenges in Powder Metallurgy Technology

Key Drivers: The primary forces propelling the Powder Metallurgy Technology market are technological advancements in powder production and sintering processes, enabling the creation of complex and high-performance parts. The increasing demand for lightweight and durable components, particularly in the automotive and aerospace industries, is a significant driver. Furthermore, cost-effectiveness due to reduced material waste and less post-processing, coupled with growing environmental consciousness promoting sustainable manufacturing practices, are vital growth catalysts.

Key Barriers & Challenges: Despite its growth, the market faces challenges such as the high initial investment required for specialized equipment and powder production. The availability and cost of high-quality metal powders can also be a constraint. Stringent quality control for consistency and defect detection remains a critical aspect. Regulatory hurdles concerning material handling and safety, along with competition from established traditional manufacturing methods, also present obstacles. Supply chain disruptions for raw materials and the need for specialized skilled labor are ongoing concerns impacting the sector.

Emerging Opportunities in Powder Metallurgy Technology

Emerging opportunities in Powder Metallurgy Technology lie in the burgeoning field of additive manufacturing (3D printing), where metal powder-based technologies are enabling the creation of highly customized and complex components for aerospace, healthcare, and specialized industrial applications. The development of new functional materials, such as porous metal structures for filtration and biomedical implants, presents significant growth avenues. Untapped markets in emerging economies, driven by industrialization and increasing demand for advanced manufacturing solutions, offer substantial potential. Evolving consumer preferences for personalized and high-performance products across various sectors will continue to fuel demand for innovative powder metallurgy solutions.

Growth Accelerators in the Powder Metallurgy Technology Industry

The long-term growth of the Powder Metallurgy Technology industry is being catalyzed by continuous technological breakthroughs in powder metallurgy techniques, including advancements in binder jetting and selective laser melting for additive manufacturing. Strategic partnerships between powder manufacturers, equipment providers, and end-users are fostering innovation and accelerating product development. Market expansion strategies focusing on emerging economies and niche high-value applications, such as biomedical devices and specialized tooling, are also key growth accelerators. The integration of artificial intelligence and machine learning in process optimization and quality control further enhances efficiency and product consistency, driving broader adoption.

Key Players Shaping the Powder Metallurgy Technology Market

- Crucible Industries

- Kobe Steel

- Hitachi

- PMG

- Ace Powder Metallurgy

- Hoganas AB

- GKN

- Sumitomo Electric Industries

- Fine Sinter

- Miba AG

- Porite Co.,Ltd.

- AAM

- AMETEK Metals

- ATI

- Burgess-Norton

Notable Milestones in Powder Metallurgy Technology Sector

- 2019: Launch of new high-performance alloy powders by leading manufacturers, enabling new application possibilities.

- 2020: Significant investment in additive manufacturing capabilities by key powder metallurgy players.

- 2021: Advancements in sustainable powder production methods gaining traction.

- 2022: Major M&A activity leading to consolidation and enhanced market presence of key players.

- 2023: Increased adoption of powder metallurgy for electric vehicle components and battery systems.

- 2024: Development of novel powder processing techniques for finer particle sizes and enhanced properties.

In-Depth Powder Metallurgy Technology Market Outlook

- 2019: Launch of new high-performance alloy powders by leading manufacturers, enabling new application possibilities.

- 2020: Significant investment in additive manufacturing capabilities by key powder metallurgy players.

- 2021: Advancements in sustainable powder production methods gaining traction.

- 2022: Major M&A activity leading to consolidation and enhanced market presence of key players.

- 2023: Increased adoption of powder metallurgy for electric vehicle components and battery systems.

- 2024: Development of novel powder processing techniques for finer particle sizes and enhanced properties.

In-Depth Powder Metallurgy Technology Market Outlook

The future of Powder Metallurgy Technology is exceptionally promising, driven by an accelerating synergy between material science innovation and advanced manufacturing processes. Growth accelerators, including the expanding role of additive manufacturing, the development of high-performance alloy powders, and strategic market penetration into emerging economies, will continue to shape the industry landscape. The increasing demand for sustainable and efficient manufacturing solutions, coupled with the inherent advantages of powder metallurgy in producing complex, lightweight, and durable components, positions the sector for sustained and robust expansion. Strategic partnerships and ongoing technological advancements will unlock new application frontiers, solidifying powder metallurgy's position as a cornerstone of next-generation manufacturing.

Powder Metallurgy Technology Segmentation

-

1. Application

- 1.1. Automotive

- 1.2. Electrical and Electronics

- 1.3. Industrial

- 1.4. Other

-

2. Types

- 2.1. Metallic Material(like Powder Metallurgy Steel)

- 2.2. Component Products

Powder Metallurgy Technology Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Powder Metallurgy Technology REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Powder Metallurgy Technology Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Automotive

- 5.1.2. Electrical and Electronics

- 5.1.3. Industrial

- 5.1.4. Other

- 5.2. Market Analysis, Insights and Forecast - by Types

- 5.2.1. Metallic Material(like Powder Metallurgy Steel)

- 5.2.2. Component Products

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Powder Metallurgy Technology Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Automotive

- 6.1.2. Electrical and Electronics

- 6.1.3. Industrial

- 6.1.4. Other

- 6.2. Market Analysis, Insights and Forecast - by Types

- 6.2.1. Metallic Material(like Powder Metallurgy Steel)

- 6.2.2. Component Products

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Powder Metallurgy Technology Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Automotive

- 7.1.2. Electrical and Electronics

- 7.1.3. Industrial

- 7.1.4. Other

- 7.2. Market Analysis, Insights and Forecast - by Types

- 7.2.1. Metallic Material(like Powder Metallurgy Steel)

- 7.2.2. Component Products

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Powder Metallurgy Technology Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Automotive

- 8.1.2. Electrical and Electronics

- 8.1.3. Industrial

- 8.1.4. Other

- 8.2. Market Analysis, Insights and Forecast - by Types

- 8.2.1. Metallic Material(like Powder Metallurgy Steel)

- 8.2.2. Component Products

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Powder Metallurgy Technology Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Automotive

- 9.1.2. Electrical and Electronics

- 9.1.3. Industrial

- 9.1.4. Other

- 9.2. Market Analysis, Insights and Forecast - by Types

- 9.2.1. Metallic Material(like Powder Metallurgy Steel)

- 9.2.2. Component Products

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Powder Metallurgy Technology Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Automotive

- 10.1.2. Electrical and Electronics

- 10.1.3. Industrial

- 10.1.4. Other

- 10.2. Market Analysis, Insights and Forecast - by Types

- 10.2.1. Metallic Material(like Powder Metallurgy Steel)

- 10.2.2. Component Products

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Crucible Industries

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Kobe Steel

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Hitachi

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 PMG

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Ace Powder Metallurgy

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Hoganas AB

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 GKN

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Sumitomo Electric Industries

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Fine Sinter

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Miba AG

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Porite Co.

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Ltd.

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 AAM

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 AMETEK Metals

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 ATI

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 Burgess-Norton

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.1 Crucible Industries

List of Figures

- Figure 1: Global Powder Metallurgy Technology Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Powder Metallurgy Technology Revenue (million), by Application 2024 & 2032

- Figure 3: North America Powder Metallurgy Technology Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Powder Metallurgy Technology Revenue (million), by Types 2024 & 2032

- Figure 5: North America Powder Metallurgy Technology Revenue Share (%), by Types 2024 & 2032

- Figure 6: North America Powder Metallurgy Technology Revenue (million), by Country 2024 & 2032

- Figure 7: North America Powder Metallurgy Technology Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Powder Metallurgy Technology Revenue (million), by Application 2024 & 2032

- Figure 9: South America Powder Metallurgy Technology Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Powder Metallurgy Technology Revenue (million), by Types 2024 & 2032

- Figure 11: South America Powder Metallurgy Technology Revenue Share (%), by Types 2024 & 2032

- Figure 12: South America Powder Metallurgy Technology Revenue (million), by Country 2024 & 2032

- Figure 13: South America Powder Metallurgy Technology Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Powder Metallurgy Technology Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Powder Metallurgy Technology Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Powder Metallurgy Technology Revenue (million), by Types 2024 & 2032

- Figure 17: Europe Powder Metallurgy Technology Revenue Share (%), by Types 2024 & 2032

- Figure 18: Europe Powder Metallurgy Technology Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Powder Metallurgy Technology Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Powder Metallurgy Technology Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Powder Metallurgy Technology Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Powder Metallurgy Technology Revenue (million), by Types 2024 & 2032

- Figure 23: Middle East & Africa Powder Metallurgy Technology Revenue Share (%), by Types 2024 & 2032

- Figure 24: Middle East & Africa Powder Metallurgy Technology Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Powder Metallurgy Technology Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Powder Metallurgy Technology Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Powder Metallurgy Technology Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Powder Metallurgy Technology Revenue (million), by Types 2024 & 2032

- Figure 29: Asia Pacific Powder Metallurgy Technology Revenue Share (%), by Types 2024 & 2032

- Figure 30: Asia Pacific Powder Metallurgy Technology Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Powder Metallurgy Technology Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Powder Metallurgy Technology Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Powder Metallurgy Technology Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Powder Metallurgy Technology Revenue million Forecast, by Types 2019 & 2032

- Table 4: Global Powder Metallurgy Technology Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Powder Metallurgy Technology Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Powder Metallurgy Technology Revenue million Forecast, by Types 2019 & 2032

- Table 7: Global Powder Metallurgy Technology Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Powder Metallurgy Technology Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Powder Metallurgy Technology Revenue million Forecast, by Types 2019 & 2032

- Table 13: Global Powder Metallurgy Technology Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Powder Metallurgy Technology Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Powder Metallurgy Technology Revenue million Forecast, by Types 2019 & 2032

- Table 19: Global Powder Metallurgy Technology Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Powder Metallurgy Technology Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Powder Metallurgy Technology Revenue million Forecast, by Types 2019 & 2032

- Table 31: Global Powder Metallurgy Technology Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Powder Metallurgy Technology Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Powder Metallurgy Technology Revenue million Forecast, by Types 2019 & 2032

- Table 40: Global Powder Metallurgy Technology Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Powder Metallurgy Technology Revenue (million) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Powder Metallurgy Technology?

The projected CAGR is approximately XX%.

2. Which companies are prominent players in the Powder Metallurgy Technology?

Key companies in the market include Crucible Industries, Kobe Steel, Hitachi, PMG, Ace Powder Metallurgy, Hoganas AB, GKN, Sumitomo Electric Industries, Fine Sinter, Miba AG, Porite Co., Ltd., AAM, AMETEK Metals, ATI, Burgess-Norton.

3. What are the main segments of the Powder Metallurgy Technology?

The market segments include Application, Types.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4900.00, USD 7350.00, and USD 9800.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Powder Metallurgy Technology," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Powder Metallurgy Technology report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Powder Metallurgy Technology?

To stay informed about further developments, trends, and reports in the Powder Metallurgy Technology, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence