Key Insights

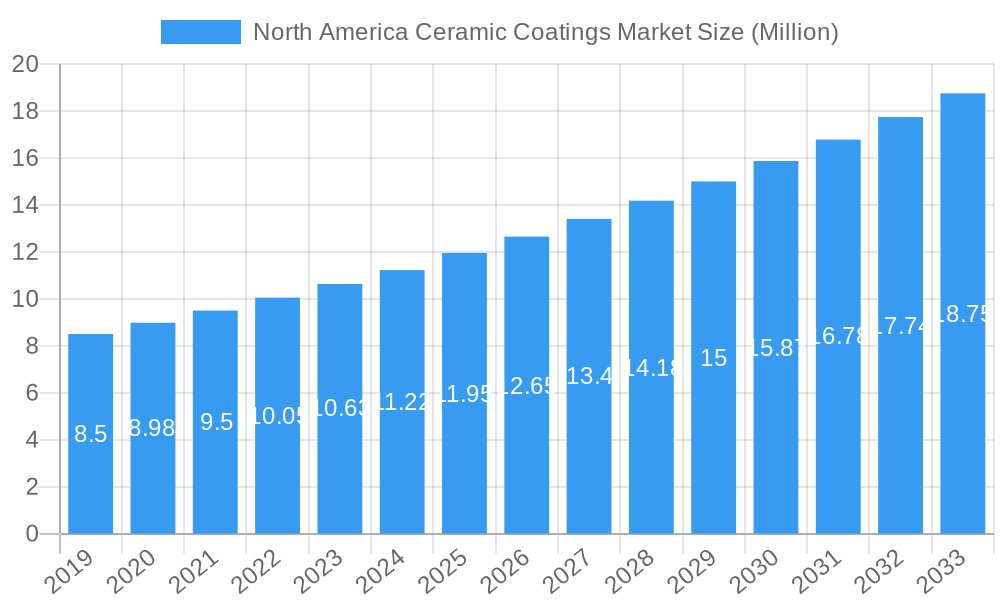

The North America Ceramic Coatings Market is poised for robust growth, projected to reach $11.95 billion in 2025 and expand at a Compound Annual Growth Rate (CAGR) of 5.9% through 2033. This expansion is fueled by the increasing demand for advanced materials that offer superior performance in harsh environments, particularly within the aerospace and defense, transportation, and healthcare sectors. Ceramic coatings are critical for enhancing durability, wear resistance, thermal insulation, and corrosion protection across a wide array of applications. The transportation industry, for instance, is leveraging these coatings to improve fuel efficiency and extend the lifespan of critical components. Similarly, the healthcare sector benefits from biocompatible ceramic coatings for implants and medical devices.

North America Ceramic Coatings Market Market Size (In Million)

Key market drivers include technological advancements in coating application methods such as Thermal Spray, Physical Vapor Deposition (PVD), and Chemical Vapor Deposition (CVD), which enable more precise and cost-effective application. The growing emphasis on sustainability and the need for longer-lasting components across all industries also contribute significantly to market expansion. While the market is driven by these factors, potential restraints could include the initial high cost of some advanced ceramic materials and specialized application equipment, alongside the need for skilled labor for precise application. However, the inherent benefits and growing adoption rates are expected to outweigh these challenges, solidifying the positive growth trajectory for the North America Ceramic Coatings Market.

North America Ceramic Coatings Market Company Market Share

Here is a compelling, SEO-optimized report description for the North America Ceramic Coatings Market, integrating high-traffic keywords and structured for maximum impact:

North America Ceramic Coatings Market: Comprehensive Analysis 2019–2033

This in-depth report offers a definitive exploration of the North America Ceramic Coatings Market, meticulously detailing its current state and future trajectory. Spanning the study period of 2019–2033, with a base year of 2025, this analysis provides critical insights into market size, growth drivers, regional dominance, technological advancements, and competitive landscapes. Essential for stakeholders in aerospace and defense, transportation, healthcare, energy and power, and industrial sectors, this report is your indispensable guide to navigating the evolving North American advanced coatings industry. Discover emerging opportunities and strategic imperatives in a market projected to reach significant value by 2033.

North America Ceramic Coatings Market Market Dynamics & Structure

The North America Ceramic Coatings Market is characterized by moderate to high concentration, driven by significant technological innovation and stringent regulatory frameworks, particularly in the aerospace and defense, and healthcare industries. Key drivers of technological innovation include the demand for enhanced material performance, such as extreme temperature resistance, wear resistance, and corrosion protection, pushing the development of advanced ceramic materials like carbides and nitrides. Regulatory bodies, especially in North America, implement standards that influence product development and adoption, ensuring safety and efficacy. Competitive product substitutes, while present in some lower-end applications, are largely outpaced by the unique performance attributes of ceramic coatings in demanding environments. End-user demographics are shifting, with a growing demand for lightweight, durable, and sustainable solutions across various sectors. Mergers and acquisitions (M&A) are moderately active, with larger players acquiring niche specialists to expand their technological portfolios and market reach. For instance, M&A deal volumes have seen a consistent uptick over the historical period, reflecting consolidation and strategic expansion efforts. Barriers to innovation include the high cost of R&D and specialized manufacturing equipment required for advanced ceramic coating technologies like PVD and CVD.

- Market Concentration: Moderate to High, with key players holding significant market share.

- Technological Innovation Drivers: Extreme temperature resistance, wear resistance, corrosion protection, lightweighting.

- Regulatory Frameworks: Influence product development and adoption in critical industries.

- Competitive Product Substitutes: Limited impact in high-performance applications.

- End-user Demographics: Increasing demand for durability, sustainability, and advanced performance.

- M&A Trends: Moderate activity, focused on portfolio expansion and technological integration.

- Innovation Barriers: High R&D costs and specialized manufacturing requirements.

North America Ceramic Coatings Market Growth Trends & Insights

The North America Ceramic Coatings Market is poised for robust expansion, driven by escalating demand across its diverse end-user industries. The market size evolution is significantly influenced by technological disruptions and a discernible shift in consumer and industrial behavior towards high-performance, long-lasting solutions. Adoption rates for ceramic coatings are steadily increasing as their superior properties—including exceptional hardness, thermal insulation, chemical inertness, and electrical insulation—become more widely recognized and economically viable for a broader range of applications. For instance, the adoption of thermal spray coatings has seen substantial growth due to their cost-effectiveness and versatility in repairing and enhancing component performance in the energy and power sector, as well as in the transportation industry for wear-resistant parts. Technological advancements, such as the refinement of Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) techniques, are enabling the application of thinner, more uniform, and highly functional ceramic layers, thereby expanding their utility in sophisticated applications within aerospace and defense and healthcare, particularly for medical implants and surgical instruments requiring biocompatibility and wear resistance.

Consumer behavior is also indirectly impacting this market; as industries prioritize product longevity, reduced maintenance, and improved energy efficiency, the demand for materials that offer these benefits, such as ceramic coatings, intensifies. The CAGR for the North America Ceramic Coatings Market is estimated to be approximately XX% during the forecast period (2025–2033), a testament to its sustained growth trajectory. Market penetration is deepening across all key segments, with particular acceleration in specialized niches driven by miniaturization in electronics and the development of advanced materials for renewable energy technologies. The shift towards electric vehicles (EVs) and advanced aerospace designs also presents a significant growth avenue, requiring innovative thermal management and wear protection solutions that ceramic coatings are uniquely positioned to provide. The increasing focus on sustainability and a circular economy further favors ceramic coatings due to their role in extending product lifespans and reducing the need for replacement. The market penetration is currently estimated at XX% for industrial applications and is projected to grow substantially in the healthcare sector.

Dominant Regions, Countries, or Segments in North America Ceramic Coatings Market

The United States stands out as the dominant region within the North America Ceramic Coatings Market, driven by its advanced industrial infrastructure, substantial investments in research and development, and a strong presence of key end-user industries like aerospace, defense, and healthcare. The US market's dominance is further bolstered by its robust manufacturing capabilities and early adoption of cutting-edge technologies, including advanced thermal spray, PVD, and CVD methods for applying ceramic coatings. Economic policies favoring innovation and domestic manufacturing, coupled with significant infrastructure development initiatives, consistently fuel the demand for high-performance coatings that enhance durability, efficiency, and safety across various applications.

Geographically, the United States accounts for an estimated XX% of the total North American market share. This leadership is attributed to a confluence of factors:

- Technological Hubs: Proximity to leading research institutions and technology parks fosters rapid innovation and commercialization of new ceramic coating materials and applications.

- End-User Industry Strength: The presence of major players in aerospace (e.g., Boeing, Lockheed Martin), automotive (e.g., Ford, GM), energy (e.g., oil and gas majors, renewable energy developers), and healthcare (e.g., medical device manufacturers) creates a consistent and substantial demand.

- Investment in R&D: Significant private and public investment in advanced materials research drives the development of next-generation ceramic coatings.

Among the segments, Oxide ceramic coatings hold a significant market share due to their widespread use in thermal barrier applications, corrosion resistance, and as electrical insulators in the energy and industrial sectors. However, Carbide and Nitride coatings are experiencing rapid growth, particularly in applications demanding extreme wear resistance and hardness, such as in cutting tools, engine components, and industrial machinery. The Aerospace and Defense end-user industry is a primary growth driver, demanding high-performance ceramic coatings for turbine blades, engine components, and structural parts, where exceptional temperature and wear resistance are paramount. The Transportation sector, especially with the rise of electric vehicles and advanced engine technologies, is another critical segment, seeking coatings for battery thermal management, wear reduction in drivetrains, and lightweighting solutions. The Healthcare industry's demand for biocompatible, wear-resistant, and antimicrobial coatings for implants and surgical instruments is also a significant contributor to market growth.

The Thermal Spray technology segment remains dominant due to its cost-effectiveness and versatility in applying a wide range of ceramic materials. However, Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) technologies are witnessing accelerated growth, driven by the demand for highly precise, thin, and complex coatings in high-tech industries like electronics and advanced medical devices. The market share for thermal spray technology is approximately XX%, while PVD and CVD collectively account for XX% and are projected to grow at a higher CAGR.

North America Ceramic Coatings Market Product Landscape

The North America Ceramic Coatings Market product landscape is characterized by continuous innovation in material science and application technologies. Leading companies are focusing on developing enhanced formulations of carbide, nitride, and oxide coatings to meet increasingly stringent performance demands. Product innovations include advanced thermal barrier coatings for extreme environments, superhard coatings for wear-intensive applications, and biocompatible coatings for the medical sector. Applications are expanding from traditional industrial uses to cutting-edge sectors such as renewable energy components, advanced electronics, and next-generation aerospace propulsion systems. Performance metrics like improved wear resistance (up to XX% increase), enhanced thermal insulation (reducing heat transfer by XX%), and superior corrosion resistance are key selling propositions. Technological advancements in deposition techniques like high-velocity oxygen fuel (HVOF) thermal spray and magnetron sputtering PVD are enabling thinner, more adherent, and defect-free coatings.

Key Drivers, Barriers & Challenges in North America Ceramic Coatings Market

Key Drivers: The North America Ceramic Coatings Market is propelled by the escalating demand for high-performance materials that offer superior durability, wear resistance, thermal management, and corrosion protection across a multitude of industries. Technological advancements in deposition techniques, such as PVD and CVD, are enabling more precise and functional coatings. The growing emphasis on energy efficiency and product longevity in sectors like aerospace, transportation (including EVs), and energy generation directly fuels the need for advanced ceramic coatings. Furthermore, the increasing stringency of regulatory requirements in industries like healthcare and aerospace necessitates the use of biocompatible and high-reliability materials.

Barriers & Challenges: Despite robust growth drivers, the market faces several challenges. The high initial cost of R&D and specialized manufacturing equipment for advanced ceramic coatings can be a significant barrier, especially for smaller enterprises. Supply chain complexities for raw materials and specialized equipment can lead to production delays and increased costs. Regulatory hurdles, while often drivers for innovation, can also create compliance challenges and slow down product adoption. Intense competition from alternative material solutions and established coating technologies also presents a restraint. Furthermore, the skilled labor shortage for operating and maintaining advanced coating equipment poses an ongoing challenge to market expansion and efficiency. The cost of advanced PVD and CVD equipment can range from $XXX,XXX to $X,XXX,XXX, impacting market entry for new players.

Emerging Opportunities in North America Ceramic Coatings Market

Emerging opportunities within the North America Ceramic Coatings Market are largely driven by the burgeoning sectors of renewable energy and advanced electronics. The development of enhanced coatings for solar panels to improve efficiency and durability, alongside specialized coatings for wind turbine components to combat erosion and corrosion, presents significant untapped potential. In the electronics sector, the demand for ultra-thin, highly insulating, and heat-dissipating ceramic coatings for advanced semiconductors and next-generation displays is rapidly growing. The automotive industry's shift towards electric vehicles opens avenues for coatings that enhance battery thermal management, protect electric motor components, and reduce overall vehicle weight. Furthermore, the expanding use of additive manufacturing (3D printing) offers new possibilities for the application of ceramic coatings on complex geometries, creating opportunities for customized and integrated solutions. The increasing focus on sustainable manufacturing practices also presents opportunities for ceramic coatings that extend product lifecycles and reduce waste.

Growth Accelerators in the North America Ceramic Coatings Market Industry

The long-term growth of the North America Ceramic Coatings Market is being significantly accelerated by ongoing technological breakthroughs, strategic market expansion initiatives, and synergistic partnerships. Continuous advancements in material science are leading to the development of novel ceramic compositions with unprecedented performance characteristics, such as ultra-high temperature resistance and superior tribological properties, catering to extreme applications. The increasing adoption of these advanced coatings in critical sectors like advanced aerospace propulsion systems and next-generation energy storage solutions acts as a major catalyst. Strategic market expansion by key players into emerging application niches, coupled with significant investments in R&D to drive innovation, further fuels growth. Collaborations and partnerships between coating manufacturers, material suppliers, and end-users are crucial for accelerating the development and commercialization of tailored solutions, thereby fostering market penetration and driving sustained growth.

Key Players Shaping the North America Ceramic Coatings Market Market

- APS Materials Inc

- A&A Thermal Spray Coatings

- Aremco

- Praxair S T Technology Inc (Linde Plc)

- Saint-Gobain

- Fosbel Inc

- OC Oerlikon Management AG

- Kurt J Lesker Company

- Swain Tech Coatings Inc

- Bodycote

- Waipolon International Co Ltd

Notable Milestones in North America Ceramic Coatings Market Sector

- 2022: Introduction of novel graphene-enhanced ceramic coatings for aerospace engine components, promising significant improvements in thermal resistance and wear performance.

- 2021: Expansion of manufacturing capacity for PVD and CVD ceramic coatings by major players to meet the surging demand from the electronics and healthcare sectors.

- 2020: Launch of new biocompatible ceramic coatings for orthopedic implants, demonstrating superior integration and longevity in human body applications.

- 2019: Significant investment in R&D by leading companies to develop sustainable and environmentally friendly ceramic coating solutions.

- 2019: Increased adoption of atmospheric outer spray technology for large-scale industrial applications, offering cost-effective protection.

In-Depth North America Ceramic Coatings Market Market Outlook

The future outlook for the North America Ceramic Coatings Market is exceptionally promising, primarily fueled by the continued demand for high-performance materials in critical industries and the relentless pace of technological innovation. Growth accelerators such as advancements in material science, leading to coatings with enhanced thermal, wear, and corrosion resistance, will continue to drive adoption in aerospace, defense, and energy sectors. The expanding applications in the transportation sector, particularly with the rise of electric vehicles requiring advanced thermal management solutions, and the healthcare industry's persistent need for biocompatible and durable coatings for medical devices, represent significant growth opportunities. Strategic market expansion, coupled with synergistic partnerships aimed at developing tailored solutions, will further propel the market forward, solidifying its trajectory towards substantial growth and innovation in the coming years.

North America Ceramic Coatings Market Segmentation

-

1. Type

- 1.1. Carbide

- 1.2. Nitride

- 1.3. Oxide

- 1.4. Other Types

-

2. Technology

- 2.1. Thermal Spray

- 2.2. Physical Vapor Deposition

- 2.3. Chemical Vapor Deposition

- 2.4. Atmospheric Outer Spray

- 2.5. Other Technologies

-

3. End-user Industry

- 3.1. Aerospace and Defense

- 3.2. Transportation

- 3.3. Healthcare

- 3.4. Energy and Power

- 3.5. Industrial

- 3.6. Other End-user Industries

-

4. Geography

- 4.1. United States

- 4.2. Canada

- 4.3. Mexico

- 4.4. Rest of North America

North America Ceramic Coatings Market Segmentation By Geography

- 1. United States

- 2. Canada

- 3. Mexico

- 4. Rest of North America

North America Ceramic Coatings Market Regional Market Share

Geographic Coverage of North America Ceramic Coatings Market

North America Ceramic Coatings Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.9% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. ; Growing Aerospace Thermal Applications; Increasing Usage in Medical Devices

- 3.3. Market Restrains

- 3.3.1. ; Higher Costs of Ceramic Coatings; Capital Intensive Production Setup; Issues Regarding Thermal Spray Process Reliability and Consistency

- 3.4. Market Trends

- 3.4.1. Aerospace and Defense Segment to Dominate the Market Demand

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. North America Ceramic Coatings Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Carbide

- 5.1.2. Nitride

- 5.1.3. Oxide

- 5.1.4. Other Types

- 5.2. Market Analysis, Insights and Forecast - by Technology

- 5.2.1. Thermal Spray

- 5.2.2. Physical Vapor Deposition

- 5.2.3. Chemical Vapor Deposition

- 5.2.4. Atmospheric Outer Spray

- 5.2.5. Other Technologies

- 5.3. Market Analysis, Insights and Forecast - by End-user Industry

- 5.3.1. Aerospace and Defense

- 5.3.2. Transportation

- 5.3.3. Healthcare

- 5.3.4. Energy and Power

- 5.3.5. Industrial

- 5.3.6. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Geography

- 5.4.1. United States

- 5.4.2. Canada

- 5.4.3. Mexico

- 5.4.4. Rest of North America

- 5.5. Market Analysis, Insights and Forecast - by Region

- 5.5.1. United States

- 5.5.2. Canada

- 5.5.3. Mexico

- 5.5.4. Rest of North America

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. United States North America Ceramic Coatings Market Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Carbide

- 6.1.2. Nitride

- 6.1.3. Oxide

- 6.1.4. Other Types

- 6.2. Market Analysis, Insights and Forecast - by Technology

- 6.2.1. Thermal Spray

- 6.2.2. Physical Vapor Deposition

- 6.2.3. Chemical Vapor Deposition

- 6.2.4. Atmospheric Outer Spray

- 6.2.5. Other Technologies

- 6.3. Market Analysis, Insights and Forecast - by End-user Industry

- 6.3.1. Aerospace and Defense

- 6.3.2. Transportation

- 6.3.3. Healthcare

- 6.3.4. Energy and Power

- 6.3.5. Industrial

- 6.3.6. Other End-user Industries

- 6.4. Market Analysis, Insights and Forecast - by Geography

- 6.4.1. United States

- 6.4.2. Canada

- 6.4.3. Mexico

- 6.4.4. Rest of North America

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. Canada North America Ceramic Coatings Market Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Carbide

- 7.1.2. Nitride

- 7.1.3. Oxide

- 7.1.4. Other Types

- 7.2. Market Analysis, Insights and Forecast - by Technology

- 7.2.1. Thermal Spray

- 7.2.2. Physical Vapor Deposition

- 7.2.3. Chemical Vapor Deposition

- 7.2.4. Atmospheric Outer Spray

- 7.2.5. Other Technologies

- 7.3. Market Analysis, Insights and Forecast - by End-user Industry

- 7.3.1. Aerospace and Defense

- 7.3.2. Transportation

- 7.3.3. Healthcare

- 7.3.4. Energy and Power

- 7.3.5. Industrial

- 7.3.6. Other End-user Industries

- 7.4. Market Analysis, Insights and Forecast - by Geography

- 7.4.1. United States

- 7.4.2. Canada

- 7.4.3. Mexico

- 7.4.4. Rest of North America

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Mexico North America Ceramic Coatings Market Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Carbide

- 8.1.2. Nitride

- 8.1.3. Oxide

- 8.1.4. Other Types

- 8.2. Market Analysis, Insights and Forecast - by Technology

- 8.2.1. Thermal Spray

- 8.2.2. Physical Vapor Deposition

- 8.2.3. Chemical Vapor Deposition

- 8.2.4. Atmospheric Outer Spray

- 8.2.5. Other Technologies

- 8.3. Market Analysis, Insights and Forecast - by End-user Industry

- 8.3.1. Aerospace and Defense

- 8.3.2. Transportation

- 8.3.3. Healthcare

- 8.3.4. Energy and Power

- 8.3.5. Industrial

- 8.3.6. Other End-user Industries

- 8.4. Market Analysis, Insights and Forecast - by Geography

- 8.4.1. United States

- 8.4.2. Canada

- 8.4.3. Mexico

- 8.4.4. Rest of North America

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Rest of North America North America Ceramic Coatings Market Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Carbide

- 9.1.2. Nitride

- 9.1.3. Oxide

- 9.1.4. Other Types

- 9.2. Market Analysis, Insights and Forecast - by Technology

- 9.2.1. Thermal Spray

- 9.2.2. Physical Vapor Deposition

- 9.2.3. Chemical Vapor Deposition

- 9.2.4. Atmospheric Outer Spray

- 9.2.5. Other Technologies

- 9.3. Market Analysis, Insights and Forecast - by End-user Industry

- 9.3.1. Aerospace and Defense

- 9.3.2. Transportation

- 9.3.3. Healthcare

- 9.3.4. Energy and Power

- 9.3.5. Industrial

- 9.3.6. Other End-user Industries

- 9.4. Market Analysis, Insights and Forecast - by Geography

- 9.4.1. United States

- 9.4.2. Canada

- 9.4.3. Mexico

- 9.4.4. Rest of North America

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Competitive Analysis

- 10.1. Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 APS Materials Inc

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 A&A Thermal Spray Coatings

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 Aremco

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Praxair S T Technology Inc (Linde Plc)

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 Saint-Gobain

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Fosbel Inc

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 OC Oerlikon Management AG

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 Kurt J Lesker Company

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 Swain Tech Coatings Inc

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Bodycote

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 Waipolon International Co Ltd*List Not Exhaustive

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.1 APS Materials Inc

List of Figures

- Figure 1: North America Ceramic Coatings Market Revenue Breakdown (undefined, %) by Product 2025 & 2033

- Figure 2: North America Ceramic Coatings Market Share (%) by Company 2025

List of Tables

- Table 1: North America Ceramic Coatings Market Revenue undefined Forecast, by Type 2020 & 2033

- Table 2: North America Ceramic Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 3: North America Ceramic Coatings Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 4: North America Ceramic Coatings Market Revenue undefined Forecast, by Geography 2020 & 2033

- Table 5: North America Ceramic Coatings Market Revenue undefined Forecast, by Region 2020 & 2033

- Table 6: North America Ceramic Coatings Market Revenue undefined Forecast, by Type 2020 & 2033

- Table 7: North America Ceramic Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 8: North America Ceramic Coatings Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 9: North America Ceramic Coatings Market Revenue undefined Forecast, by Geography 2020 & 2033

- Table 10: North America Ceramic Coatings Market Revenue undefined Forecast, by Country 2020 & 2033

- Table 11: North America Ceramic Coatings Market Revenue undefined Forecast, by Type 2020 & 2033

- Table 12: North America Ceramic Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 13: North America Ceramic Coatings Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 14: North America Ceramic Coatings Market Revenue undefined Forecast, by Geography 2020 & 2033

- Table 15: North America Ceramic Coatings Market Revenue undefined Forecast, by Country 2020 & 2033

- Table 16: North America Ceramic Coatings Market Revenue undefined Forecast, by Type 2020 & 2033

- Table 17: North America Ceramic Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 18: North America Ceramic Coatings Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 19: North America Ceramic Coatings Market Revenue undefined Forecast, by Geography 2020 & 2033

- Table 20: North America Ceramic Coatings Market Revenue undefined Forecast, by Country 2020 & 2033

- Table 21: North America Ceramic Coatings Market Revenue undefined Forecast, by Type 2020 & 2033

- Table 22: North America Ceramic Coatings Market Revenue undefined Forecast, by Technology 2020 & 2033

- Table 23: North America Ceramic Coatings Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 24: North America Ceramic Coatings Market Revenue undefined Forecast, by Geography 2020 & 2033

- Table 25: North America Ceramic Coatings Market Revenue undefined Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the North America Ceramic Coatings Market?

The projected CAGR is approximately 5.9%.

2. Which companies are prominent players in the North America Ceramic Coatings Market?

Key companies in the market include APS Materials Inc, A&A Thermal Spray Coatings, Aremco, Praxair S T Technology Inc (Linde Plc), Saint-Gobain, Fosbel Inc, OC Oerlikon Management AG, Kurt J Lesker Company, Swain Tech Coatings Inc, Bodycote, Waipolon International Co Ltd*List Not Exhaustive.

3. What are the main segments of the North America Ceramic Coatings Market?

The market segments include Type, Technology, End-user Industry, Geography.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

; Growing Aerospace Thermal Applications; Increasing Usage in Medical Devices.

6. What are the notable trends driving market growth?

Aerospace and Defense Segment to Dominate the Market Demand.

7. Are there any restraints impacting market growth?

; Higher Costs of Ceramic Coatings; Capital Intensive Production Setup; Issues Regarding Thermal Spray Process Reliability and Consistency.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "North America Ceramic Coatings Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the North America Ceramic Coatings Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the North America Ceramic Coatings Market?

To stay informed about further developments, trends, and reports in the North America Ceramic Coatings Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence